|

|

- Stable And High Quality Torque Limiter And Overload Protection Function.

- High Strength Aluminum Alloy For The Material Of Pallet Telescopic Fork.

- Outstanding Speed And Acceleration For The Transmission Of Telescopic Fork.

- Customized Service For Stacker Automatic Telescopic Fork.

- Various Of Tests During The Production Of Stacker Automatic Telescopic Fork.

|

|

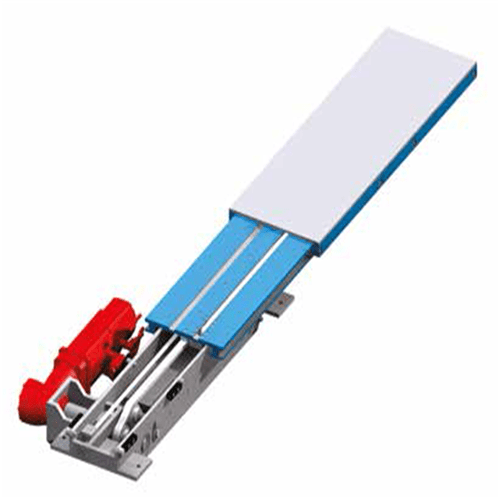

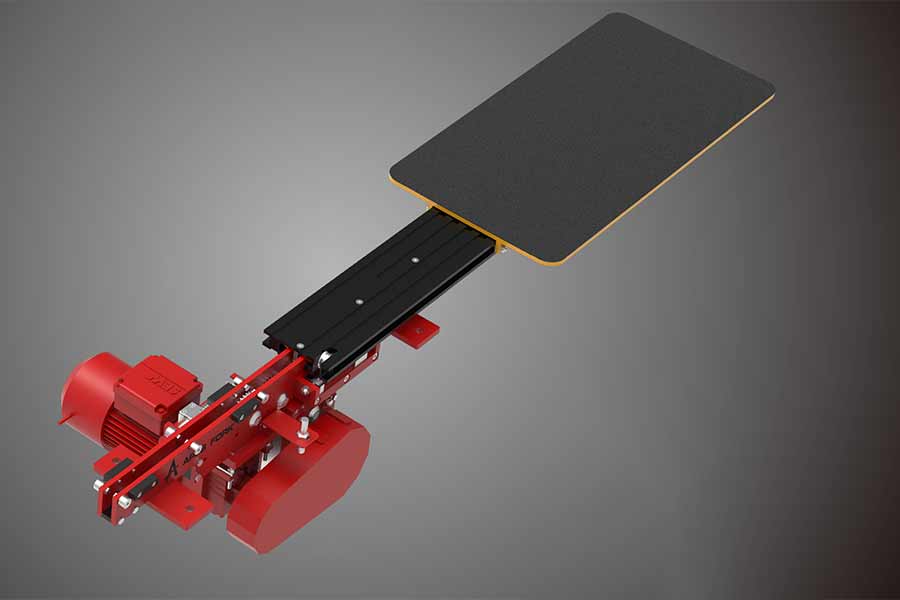

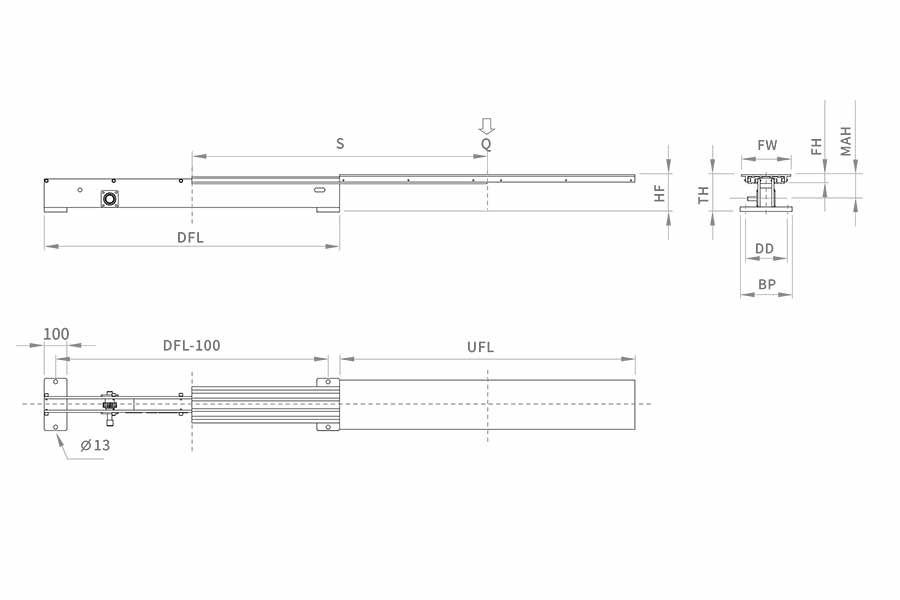

| Telescopic Slide 100 Kg 150 x 40 mm (Can Be Wider) |

Telescopic Slide 100 Kg 220 x 40 mm (Can Be Wider) |

|

|

|

|

|

|

|

|

|

|

|

|

- Used For Storage-Retrieval Of Small Volume/ Light Weight Products.

- Example – Hardware, Light Industrial Goods, Electronic Products, Food, Packaging, Etc.

- Load Handling Device For Automated Storing/ Picking Of Items.

- Can Be Mounted On Fixed / Mobile Lifting Platform.

- Drive Can Be Connected With WCS Bar-Code Signals.

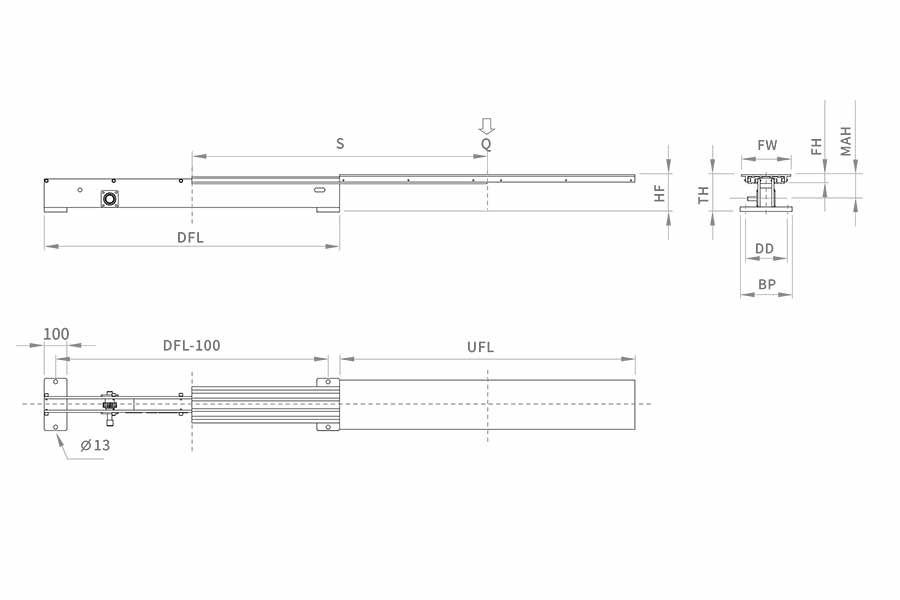

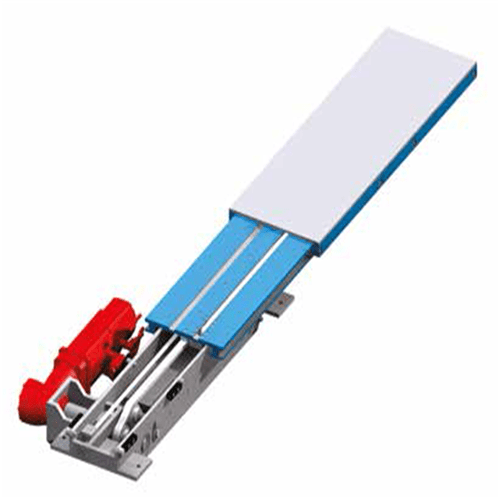

- Telescopic Fork Comprises Of Three Fork Bodies – Upper Fork (Front Fork), Intermediate Fork & Lower Fork (Fixed Body).

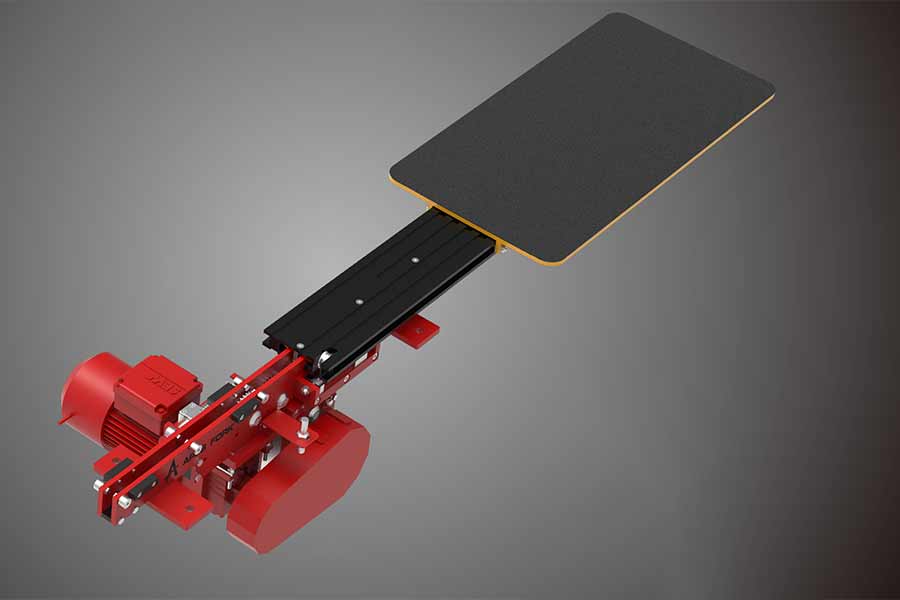

- Power Transmission Includes 100s Of Parts- Guide Slider, Limit Switch, Torque Limiter, Encoder, Drive Motor, Reducer, Coupling, etc.

- Lower Fork Installed On Cargo Platform. Intermediate Fork Driven By Rack-Pinion For Moving Outward About Half Of Its Length.

- Upper Fork Continues To Extend Outward From The Intermediate Fork’s Midpoint To Storage Location.

- Telescopic Fork Body Polished Twice.Rugged, Strong Bending Resistance.

- Less Deformation Under Over Load.German High Capacity Roller Bearings.

- TR-Electornic, Kuebler Encoders For Fast Signal Conversion & Detection. Accurate Positioning. Strong Anti-Interference Ability.

- Strong Wear Resistance. Low Friction.Used For Large Scale, Long Term, Frequent Operations.

- High Wear Resistance, High Temperature Resistance, Low Ductility.

- Standard Length 650mm, Stroke 750mm. Customized Designs Available.

|

Advantages Of Miniload Telescopic Slides

- Has High Quality Torque Limiter For Stable Overload Protection.

- Compact Coupling With Strong Angular Compensation, Ability High Transmission Performance, Large Load Capacity & Wear Resistance.

- Compact Design For Small Space Storage And Transmission.

- Upper Telescopic Fork From Lighter Weight High Strength Aluminum Alloy For Power Savings. Surface Can Be Widened To Suit Specific Needs.

- Outstanding Speed 40-60 m/min. Acceleration 0.5-2 m/s.

- Produced For Long Service Life > 1 Million Operations. Patented Design. Rugged Mechanical Structure. Precise Limit Control For Smooth Opening-Closing Operations Of Fork.

- Manufacturing Process Includes Operational Test, Lateral Deviation Detection, Torque Device Friction Plate Inspection, Load Test, Longitudinal Deviation Detection, Encoder Bushing Inspection, Deflection Test, Gear Matching Detection, Motor Speed Ratios Detection.

- Suitable For Operation From -400 To +800 F.

- High Resilence. Does Not Deform Under Long Period Operation.

- Downward Deflection Within Allowance Even Under Overload.

|

| Please also refer our other websites for AS/RS Stacker Cranes, Overhead Stacker Cranes, Shuttles Based S/RS, AGV Drives, Conveyors-Sorters, Vertical Carousels, Vertical Lift Modules, |

| We offer Telescopic Slides For Miniloads, Single Deep Telescopic Forks, Double Deep Telescopic Forks, |

| telescopic forks, miniload forks, telescopic slides, miniload extractors, miniload grippers, stacker forks, stacker crane forks, as/rs forks, agv forks, agv fork, telescopic forks, telescopic forks with belt conveyor, telescopic slides with belt conveyor, telescopic forks with roller conveyor, agv forks, shuttles forks, cold storage telescopic fork, |