|

Advantages Of Single Deep Telescopic Fork:

- Patented Design. Light Weight, Low Deflection Of 5mm.

- Power Transmission By Hardened Gears, Racks, Chains.

- High Speed 40-60 m/min. Fast Acceleration 0.5-2 m/s.

- Used For Handling Medium Size Products.

- Two-Way Telescopic Function. Convenient Exchange Mode Between One Fork With Two Forks.

- Maximum Loading Capacity Can Be Up To 400Kg.

- Standard Fork Length 650mm. Stroke 750mm.

- Customizable To Suit Client’s Needs.

- Extremely Long Life > One Million Operations.

- Less Maintenance Requirements.

|

Double Deep Telescopic Fork Are Of Two Types

One Way Double Deep Telescopic Fork – Driven By One Motor, Power Transmission By Gears, Racks, Sprockets, Chains. Upper Telescopic Fork, Upper Intermediate Telescopic Fork, Lower Intermediate Fork And Lower Telescopic Fork All Move Simultaneously.

Two Way Double Deep Telescopic Fork – Driven By Two Motors, One Motor Controls The Upper Middle Fork. Another Controls Lower Middle Telescopic Fork.

Load Capacity Of Two-Way Forks Is Higher Than Larger One-Way Forks. Most Forks Are Custom made To Suit Fork’s Length, Stroke, Load Weight, One Way-Two Way Motions.

For Safety Of Transmission And Low Deflection, The Telescopic Distance Of Upper Middle Fork And Middle Fork Body Can Not Exceed 60% Of Their Own Lengths. However, The Distance Can Be Extended Appropriately If The Load Is Lighter. |

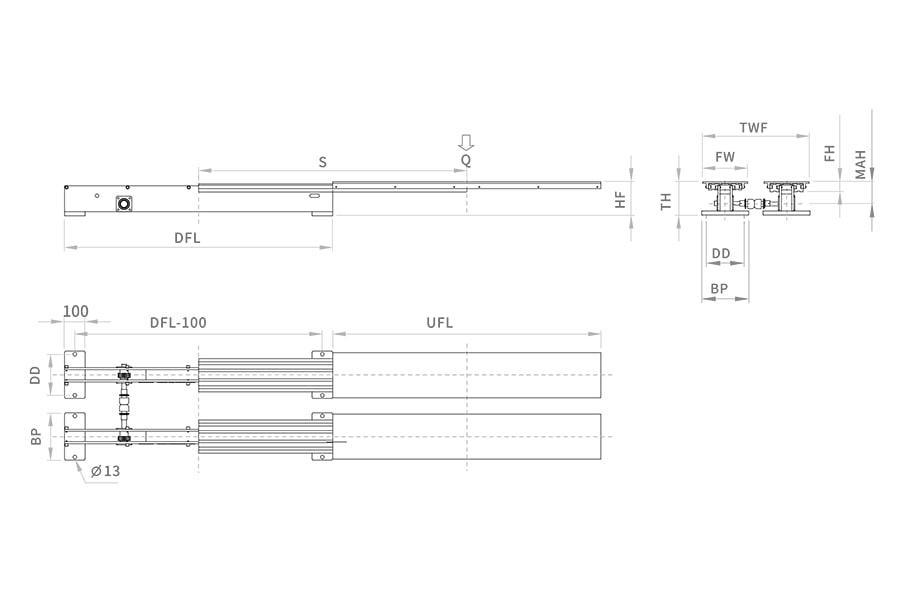

Single Deep Telescopic Fork Mechanism

- Three-Section Fork Body – Upper Fork Body, Intermediate Fork Body, Lower Fork Body.

- Power Transmission Includes 100s Of Parts- Guide Roller, Sprocket Chain, Guide Slider, Limit Switch, Torque Limiter, Encoder, Drive Motor, Reducer, Coupling, etc.

- Lower Fork Body Installed On Carriage.

- Middle Fork Body Moves Outward About Half Of Its Length Driven By Gear.

- Upper Fork Body Continues To Extend Outward From The Middle Fork’s Midpoint.

- Consists Of Two Forks.To Handle Medium Loads.

- Suited For Relatively Narrow Space Operations.

- Unified Controls- To Operate One Fork Or Two Forks Together.

|

Double Deep Telescopic Fork Mechanism

- Includes 100s Of Parts – Rollers, Roller Bearings, Gear Racks, Sprocket Chains, Guide Sliders, Travel Switch, Proximity Switch, Torque Limiter, Encoder, Driver, Motor, Reducer, Coupling, Etc.

- Consists Of 4 Major Parts.

- Lower Fork Body Installed On Carriage.

Lower Middle Fork Body Driven By Gear Rack/ Sprocket Chain Moves Outward About Half Of Its Own Length.

Upper Middle Fork Body Continues To Extend Outward From Middle Point Of Lower Middle Fork Body

Upper Fork Body Moves From Middle Of Upper Middle Fork Body To Extend Directly To Storage Location.

|

- Used For Handling Of Medium-Heavy Products- Metal Parts, Mechatronics Items, Abrasive Parts, Etc.

- Compatible With Stacker Cranes, Smart Pallet Conveyors, Barcode Detection Systems, Smart Controls- WCS, WMS, Address Recognition, Photoelectric Switch Recognition, Optical Signal Communications For Automatic Position Control.

- Single Motor Drive For Horizontal Motion Along Guiding Track Through Driving Shaft.

- Stacker Cranes Provide The Vertical Lifting Motion.

|

Telescopic Forks For Double Deep Storage Are Widely Used In Industrial Production, Equipment Manufacturing, Logistics And Warehousing, Commodity Manufacturing, Intelligent Applications, Aviation, Rail Transit, Medical Equipment, New Energy Manufacturing, Electronics Industry, Hardware And Electrical Appliances, Chemical Raw Materials, Paper Industry, Cultural Education , Tobacco Industry, Food And Beverage, Printing Iron Packaging And Other Industries. |

|

Patented Design. Manufactured With Strict QC For Precise Conveying And Positioning Systems With Compact Structure That Can Be Operated In Narrow Spaces Effectively.

Fitted With High-Quality Steel That Has Been Polished Twice With Integral Machining.

Fast Encoder Signal Conversion Detection For Accurate Positioning With Strong Anti-Interference Performance.

Compact Coupling With Strong Angular Compensation, High Transmission Efficiency, Super Load Capacity.

Equipped With EU Origin Chain That Is Wear Resistant, High Temperature Resistant, Low Ductility For Large Scale, Long Time. And Does Not Stretch Under Large Strength.

Easy To Install, Low Maintenance Needs. Long Service Life > 1 Million Operations.

Double Deep Allows Storage-Retrieval Over Large Distances |

|

|

|

|

|

|

|